Waterjet Cutting

Precise and Versatile Waterjet Cutting in Charleston, SC

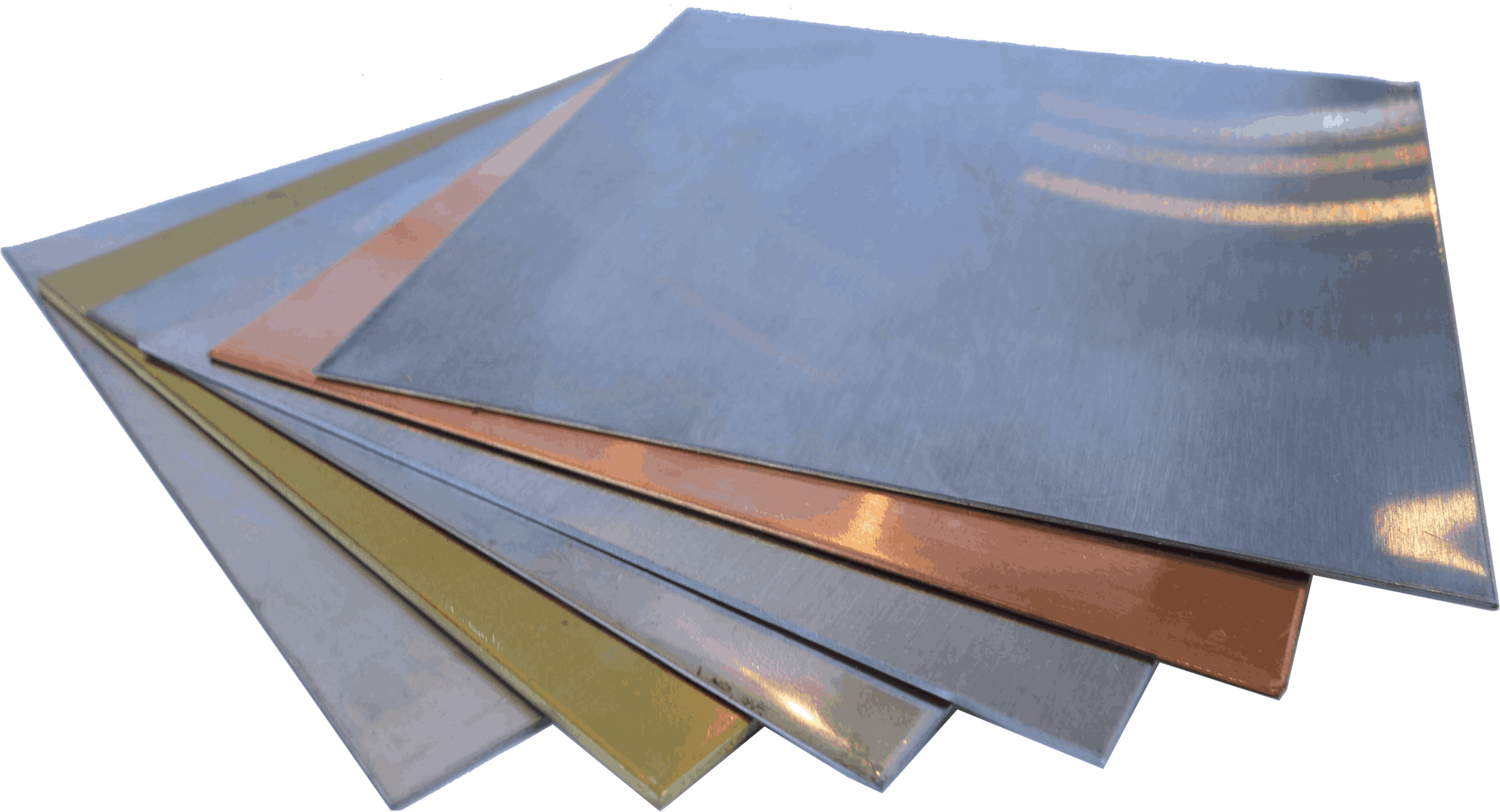

Waterjet cutting in Charleston, SC, is the answer to your precision fabrication needs. Send us your design with your metal fabrication or other material needs, and we’ll get your work onto the cutting table. Waterjet cutting can handle your project, whether it consists of rubber, steel or titanium. When your job calls for 1/8” rubber, or 1” steel, or even the rugged strength of 4” titanium, our fabrication process keeps up with the demands of the material. Talk to Charleston Rubber and Gasket Company about all your fabrication needs.

Accept No Substitutions

There is no substitute for the consistency of waterjet cutting by an experienced team of CNC experts. Our team offers the efficiency of assembly-line production with the complete freedom and accuracy of a computer-guided cutter head. We have total project control when we utilize the power of computer precision. Each machine we use has excellent tolerances and minimizes kerf, which results in less waste material. Our cutter’s ability to switch between material and thickness with no tooling changes means time saved for you. Send us your file or have us design your project. You will not be disappointed with the power of waterjet cutting.

Cuts Virtually All Materials

CNC Controlled

Variable Edge Quality

Excellent Tolerances

CHARLESTON RUBBER & GASKET UTILIZES WATERJET CUTTING FOR OUR RUBBER & GASKET FABRICATION, BUT WE ALSO OPERATE AS A FULL SERVICE WATERJET CUTTING SHOP! HERE IS WHY YOU SHOULD TAKE ADVANTAGE OF WATERJET CUTTING:

UNMATCHED DIVERSITY! WE CAN CUT 1/8" THICK GASKET SHEET AND SWITCH TO 3" THICK STAINLESS STEEL WITH NO TOOLING CHANGES.

WE CAN IMPORT YOUR FILES, CREATE NEW CAD DRAWINGS FROM SKETCHES OR SAMPLES, OR WORK WITH WHATEVER YOU HAVE TO CREATE THE PERFECT PART.

REPEATABILITY & FLEXIBILITY: GET THE EXACT SAME SHAPE EACH TIME YOU PURCHASE OR MAKE ADJUSTMENTS AS YOU GO.

MINIMIZED WASTE MEANS LOWER COST!

ADJUST EDGE QUALITY AS PER YOUR REQUIREMENTS.

NO TEMPERATURE-AFFECTED ZONES.

VERY MINIMAL KERF

EXCELLENT TOLERANCES & ACCURACY